Choosing the right materials for your surfaces is more than just because of their aesthetic values or sustainability. When discussing an appropriate material when it concerns surface designs, two names are popular: Epoxy and Phenolic. Before making the decision of which to use on your property, you need to compare and contrast, to know which one will satisfy your needs. Here is a comprehensive comparative analysis between Phenolic and epoxy.

What is epoxy resin?

Epoxy resin is a form of reactive polymer which reacts with itself or other co-reacts such as acids, alcohols, and phenols. Epoxy has good properties which makes them a good choice for most surfaces.

Properties

- Highly resistant to bacterial and fungal growth.

- Easy to maintain

- Works well on a non-porous surface

- Copes with high heat

- Scratch resistant

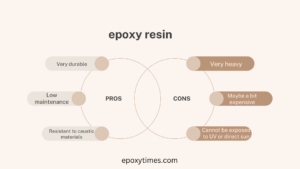

Pros

- Very durable

- Low maintenance

- Resistant to caustic materials

Cons

- Very heavy

- Maybe a bit expensive

- Cannot be exposed to UV or direct sun for a long period

What is Phenolic?

Phenolic is a quality product that is made with layering fibers that have been dipped in resin. The Phenolic resin has a tensile strength, is very versatile, and can be easily customized.

Properties

- Water resistance

- Lightweight

- Can resist many solvents and chemicals

- Affordable

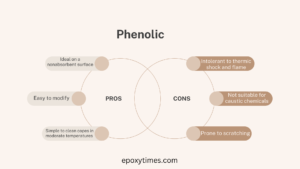

Pros

- Ideal on a nonabsorbent surface

- Easy to modify

- Simple to clean copes in moderate temperatures

Cons

- Intolerant to thermic shock and flame

- Not suitable for caustic chemicals

- Prone to scratching

Epoxy vs Phenolic: what are the similarities and differences?

When comparing epoxy and Phenolic, there are certain indices that are used for measurement.

Epoxy Vs Phenolic Resin Comparison Table

| Indices | Epoxy | Phenolic |

|---|---|---|

| Bacteria/Fungal | Highly resistant | Highly resistant |

| Chemical | Highly resistant | Moderate |

| Cost | Expensive | Cheaper |

| Heat | Cope in extreme conditions | Cope in average conditions |

| Weight | Heavy | Light |

Bacterial/Fungal Resistance

Epoxy and Phenolic products are not porous which helps them in resisting bacteria and fungi easily. Most porous surfaces have few peaks and valleys which trap germs before they grow. Because these porous and dry surfaces aren’t even, they are hard to clean. When you use epoxy or Phenolic resins, they are capable of resisting these growths and are ideal for public properties that require good sanitation.

Chemical resistance

When it comes to chemical resistance, epoxy remains the best product because it can handle many caustic materials. Although Phenolic resin resists normal chemicals and cleaners, they struggle with highly corrosive chemicals. If you properly deal with many tough chemicals, you should consider epoxy products.

Cost

Because of the heavy and dense feature of epoxy, it’s fairly expensive to get than the Phenolic resin. While it might be slightly expensive, it can last a while and requires little maintenance. However, the Phenolic resin is light and simple to ship, which makes it a cost-effective option. However, irrespective of the one you buy, the job done will determine if it saves money in the end.

If you use heavy applications, then epoxy will be a suitable option in the long run because it doesn’t need replacement like Phenolic. But for average applications, Phenolic resins are highly recommended.

Heat resistant

If you are concerned about heat, then you should buy epoxy resin. While Phenolic resin will cope well in moderate temperatures below 300 F, anything above that will be a stretch. The surface might start warping or burning.

However, epoxy can cope with extreme temperatures and open flames without any problems. So if you aren’t worried about which withstands more heat, the s go for epoxy.

Material weight

Heavy products cost more when shipping and during installation. While the epoxy resin is stronger and lasts longer, they are very heavy. Because of their heaviness and density, they are more expensive to ship than Phenolic.

Conclusion

When comparing quality coating products such as epoxy and Phenolic, several factors will help determine the ones to choose. Based on the factors above, epoxy is better when you are dealing with heavy countertops and places with too much heat, while Phenolic copes better with a place with moderate temperatures and is cheaper.